LMM for jewellery and watchmaking

Explore the potential of sinter-basd technologies

The jewellery industry has long relied on casting and, to a lesser extent, Metal Injection Moulding (MIM) for mass production. While effective, these methods restrict creativity and limit design freedom. Today, Metal Additive Manufacturing (AM) is reshaping what’s possible—offering designers the chance to create intricate, lightweight, and high-precision pieces that were once impossible to produce.

Traditionally, AM was used mainly for lost wax models to support casting, but the technology has evolved. With the rise of sinter-based AM solutions, jewellery makers can now directly produce final customer-ready parts in metals. These technologies deliver fine surface finishes, tight tolerances, and eliminate many of the barriers associated with laser-based methods.

As the market for metal AM in jewellery is set to nearly double between 2021 and 2031, innovation is accelerating across both bespoke and mass-market segments. For designers and manufacturers, this represents a true revolution in how jewellery and watch components are conceived and crafted.

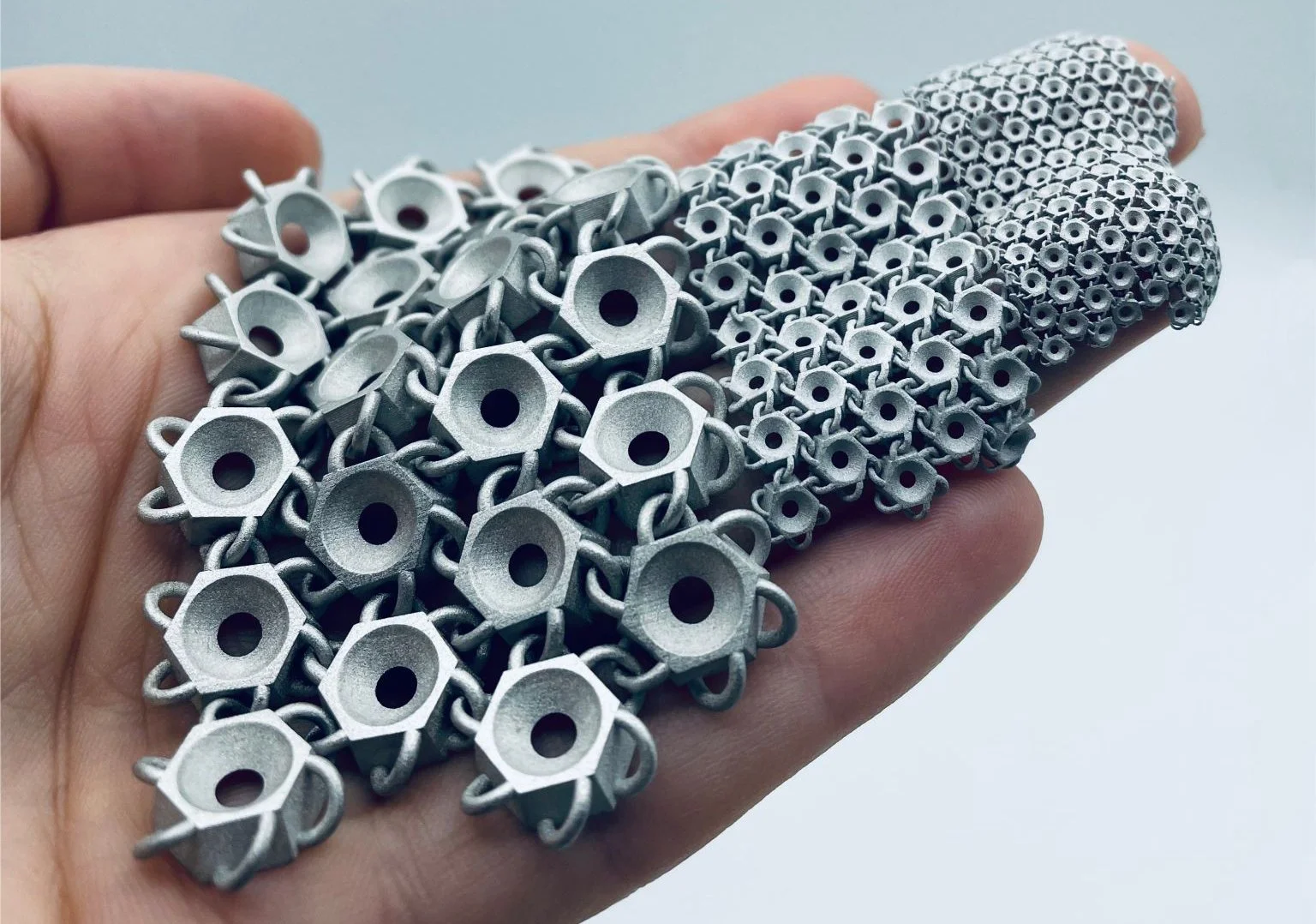

Additively manufactured steel chain in three sizes, produced via LMM