Compensating for Sintering Distortion in LMM

Compensating for Sintering Distortion in LMM: A Breakthrough in Design Readiness for High-Volume Metal Additive Manufacturing

At MetShape, we specialize in Lithography-based Metal Manufacturing (LMM), a cutting-edge sinter-based additive manufacturing (AM) technology that combines high-resolution printing with the scalability of powder metallurgy. As with all sinter-based processes, however, distortion during sintering remains a critical challenge — especially when precision, repeatability, and scalability are at stake.

That’s why we’re excited to share results from our collaborative project with the Airbus Endowed Chair for Integrated Systems in Production Engineering (ISEMP) at the University of Bremen, led by Frederik Tischel. Together, we’ve developed and validated the first dedicated simulation-based distortion compensation solution for LMM technology.

This blog dives into what distortion compensation software is, why it matters, the core functionality of the solution, and how MetShape played a key role in shaping its success.

The Challenge: Distortion in Sinter-Based Additive Manufacturing

In LMM and other sinter-based AM processes, parts are first printed from a metal-polymer feedstock and then undergo a debinding and sintering process. During sintering, the part experiences significant shrinkage and potential geometric distortion, which can be highly non-uniform due to part geometry, material properties, and processing conditions.

This distortion can result in:

Dimensional inaccuracies beyond acceptable tolerances

Mechanical performance variation

Yield losses, particularly in high-volume production

Increased manual rework and trial-and-error design cycles

In short: without a reliable prediction and compensation mechanism, LMM — despite its advantages in resolution and cost — can’t fully realize its industrial potential.

The Solution: Simulation-Based Distortion Compensation

The software developed by ISEMP offers a predictive simulation toolchain specifically tailored for LMM. This tool can calculate expected deformation and compensate the original design to ensure that the final, sintered part meets dimensional requirements.

It consists of two core components:

1. Basic Simulation Model

This core framework simulates the sintering process, accounting for factors like:

Gravity and support interaction

Geometrical stiffness of the part

Constraints from the build platform or fixtures

2. Material Model

The material model is key to accurate simulation. It reflects how a specific material responds during thermal debinding and sintering, including:

Shrinkage behavior

Viscoplastic material flow

Phase changes and thermal gradients

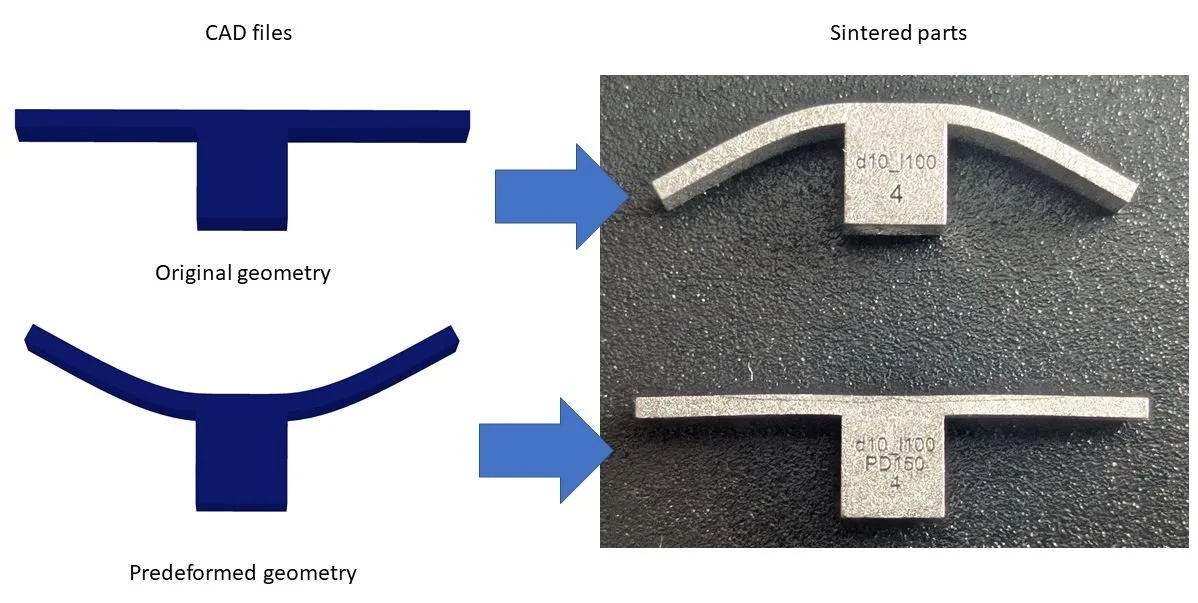

This combination of a geometric simulation engine and material-specific data allows the software to “pre-distort” the initial design in such a way that, after sintering, the part distorts into the desired shape.

Why This Is a Game-Changer for LMM

Simulation-driven compensation fundamentally changes how parts are designed and produced in LMM. Here’s why it matters:

✅ Reduced Trial-and-Error

Traditionally, distortion is addressed through multiple print-sinter-measure cycles, which are time-consuming and cost-intensive. With predictive compensation, those iterations can be drastically reduced or eliminated.

✅ Shorter Time to Production

By starting with a distortion-compensated design, manufacturers can go from concept to production-ready faster — ideal for high-volume series production where consistency is critical.

✅ Higher Dimensional Accuracy

This tool allows for tight tolerances, even in complex geometries, which opens the door for functional parts in demanding industries like aerospace, automotive, and medical.

✅ Process Chain Optimization

Designs can be integrated more effectively into the full LMM workflow — from CAD to print to sinter — ensuring a more reliable and scalable manufacturing process.

MetShape’s Role: Enabling Real-World Application Through Material Expertise

MetShape contributed a vital role in this collaboration — not only by manufacturing test parts using our industrial LMM process, but also by providing deep process and material expertise that informed the software’s material model.

> Material Parameter Study

We supported the development by identifying and quantifying key material parameters:

Sintering shrinkage rates

Thermal expansion behavior

Structural resistance under sintering conditions

These parameters are critical for the simulation model to accurately represent what happens during sintering. Our practical knowledge of the LMM process enabled the team to correlate simulation data with real-world outcomes, closing the feedback loop.

> Process Chain Validation

We also helped validate the tool across realistic geometries and production-relevant conditions. The simulation was used to compensate designs, which we then printed, sintered, and measured. The results confirmed the model’s accuracy and robustness — even for parts with significant distortion potential.

Case Results: Preforming Large-Deformed Parts Successfully

One of the highlights of this work was the successful production of highly deformed test parts that were compensated using the simulation software. These were not minor tweaks — we’re talking about large, complex deformations, and the software managed to pre-distort the input design in such a way that the sintered part met target geometry within tight tolerances.

This achievement clearly demonstrates the readiness of the tool for industrial use.

Looking Ahead: Toward Fully Automated Design for LMM

With this simulation tool, we’re taking a major step toward automated, distortion-aware design workflows for sinter-based AM. That means:

Engineers can start from intended geometry and generate distortion-compensated versions directly

Manufacturers can produce first-time-right parts, minimizing waste

LMM becomes even more viable for functional, precision components at industrial scales

At MetShape, our mission has always been to bridge the gap between AM potential and production reality. This collaboration is a perfect example of how simulation and process expertise together can unlock that next level of capability.

Conclusion

Sintering distortion is one of the most persistent challenges in sinter-based additive manufacturing — but with the development of this dedicated compensation software for LMM, we now have a reliable, predictive solution.

Through our partnership with ISEMP and Frederik Tischel, we’re proud to have contributed both in simulation validation and material modeling. This is a major step toward making LMM a truly production-ready technology, not just for prototypes, but for high-volume, high-precision applications.

We look forward to seeing this solution deployed across industries, and we remain committed to driving LMM innovation forward.