Introduction to Lithography-based metal manufacturing

Introduction

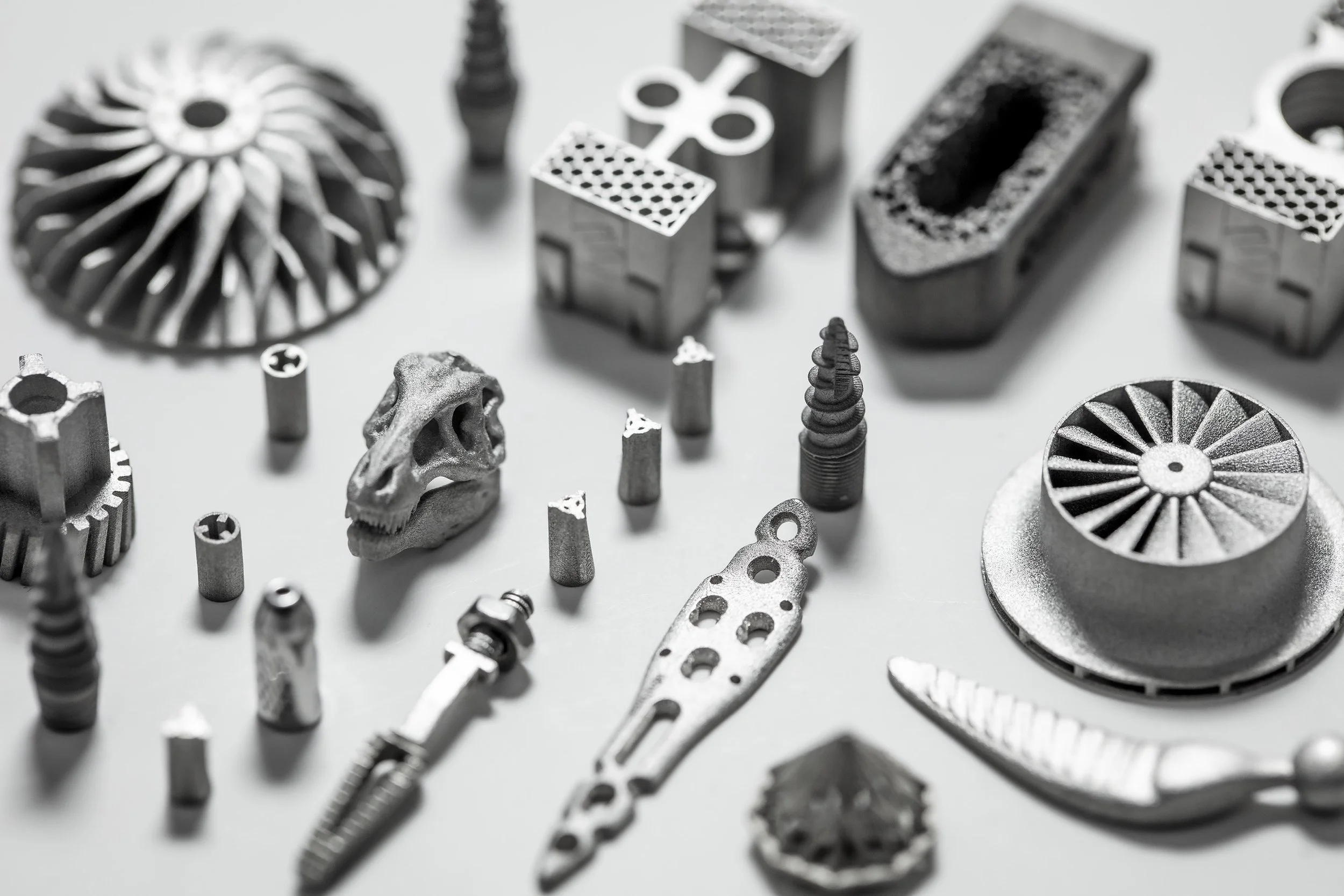

In today’s precision manufacturing landscape, lithography-based metal manufacturing (LMM) is emerging as a transformative technology for producing high-accuracy metal components. It is especially suited for small and micro parts with complex geometries and fine details, which are often challenging—or impossible—to produce with conventional methods. At MetShape GmbH, we leverage this technology to accelerate product development and manufacturing while providing deep expertise in application and material development.

What is Lithography-Based Metal Manufacturing?

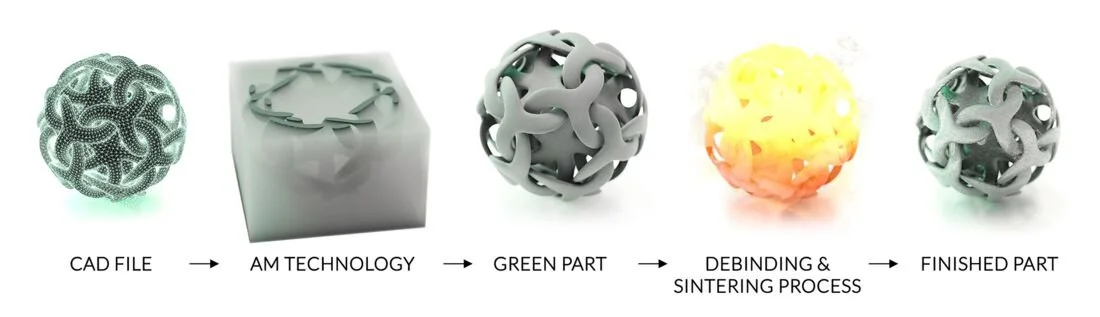

LMM is a sinter-based additive manufacturing process that combines photolithography with metal powder processing. The process begins with a feedstock consisting of metal powder mixed with a photosensitive polymer binder. This material is applied to a build platform and selectively cross-linked layer by layer using UV light through mask exposure, forming a “green part.”

The green part then undergoes debinding and sintering, resulting in a fully dense, high-strength metal component. This two-step approach offers several key advantages:

High productivity and efficient use of materials

No support structures, improving surface quality and reducing post-processing

Final part properties comparable to Metal Injection Molding (MIM)

Full design freedom of 3D printing, enabling complex and customized geometries

Key Characteristics of LMM

Ideal for small, complex parts (<30 mm)

High accuracy with tolerances of ±0.05 mm

Single-step printing, no tooling required

Layer thickness: 10–60 µm

Surface quality: Ra ~2–3 µm

Materials

MetShape offers a range of metals suitable for LMM. Standard materials include 316L stainless steel and 17-4PH stainless steel, known for their mechanical strength and corrosion resistance. For high-performance applications, we provide Titanium Grade 5, NiTiNol, and cobalt-chrome alloys, with the option for custom material development tailored to specific requirements. This enables clients to optimize parts for mechanical performance, biocompatibility, or other application-specific needs while maintaining high precision and geometric complexity.

Why LMM Excels for High-Precision, Complex Parts

High Accuracy Manufacturing: Achieve extremely tight tolerances and intricate geometries not possible with conventional methods.

Complex Small/Micro Parts: Produce the finest details, enabling innovative designs in medical, aerospace, automotive, luxury jewelry, and high-tech industrial applications.

Fast Prototyping and Iteration: Rapidly produce prototypes for quick design iterations, accelerating the development process.

Reduced Risk in Tooling: Successful LMM prototypes reduce risk when moving to traditional methods like MIM. Production can also scale gradually toward series manufacturing without compromising quality.

Design Freedom for Innovation: Leverage the full flexibility of 3D printing to create optimized geometries and higher-performing parts.

Applications Across Industries

LMM is ideal for a wide range of industries, including:

Medical devices and implants requiring micro-scale accuracy

Aerospace and high-performance components with complex geometries

Automotive parts where precision and reliability are critical

Customized industrial equipment needing rapid development

Luxury jewelry, allowing intricate and highly detailed designs

Why Choose MetShape GmbH

As a global knowledge center for LMM, MetShape GmbH masters every step of the process—from prototyping to production. We provide not only fast delivery of high-accuracy metal parts, but also application development and material optimization tailored to your needs. Our expertise enables accelerated prototyping, minimized production risk, and scalable manufacturing in line with demand.

Conclusion

Lithography-based metal manufacturing is a strong, versatile technology for producing high-accuracy, complex, and highly detailed small and micro parts. It enables rapid prototyping, fast iterations, and gradual scale-up toward series production, while fully leveraging the design freedom of 3D printing for innovation and superior part performance. At MetShape GmbH, we master the LMM process, helping clients globally to develop, optimize, and deliver cutting-edge metal components efficiently and reliably.