Titanium Grade 5 & Lithography-based Metal Manufacturing (LMM) — Key Insights

Titanium Grade 5 is one of the most advanced engineering metals. When paired with Lithography-based Metal Manufacturing (LMM), it can unlock new capabilities that go far beyond what conventional methods can achieve today — especially for small, complex parts. Here’s a deeper dive into what makes Titanium Grade 5 & LMM so powerful, the challenges, and what is the current state of the development at MetShape.

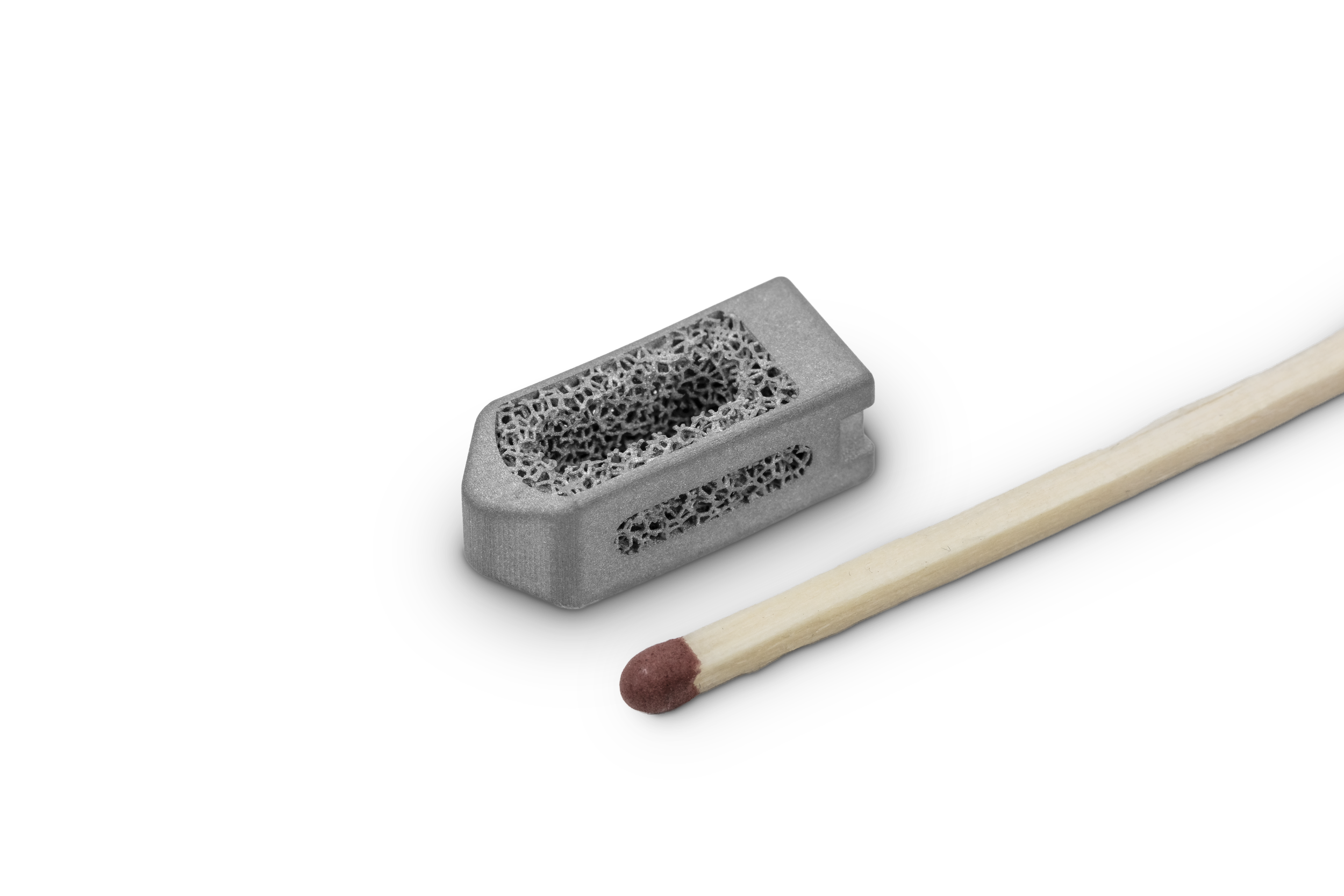

Titanium Implant 3D Printed with LMM

Titanium Grade 5: Strength, Adaptability & Efficiency

Titanium Grade 5 (Ti-6Al-4V) is widely valued for its exceptional strength-to-weight ratio, corrosion resistance, and thermal stability. In comparison to stainless steels with similar mechanical properties, its lower density enables a weight reduction of approximately 45% for equivalent components.

A key feature of titanium is its rapid formation of a stable oxide layer upon exposure to air, which provides excellent resistance to oxidation and corrosion, even in highly aggressive environments. This intrinsic passivation underlies its broad applicability, ranging from demanding engineering fields to biomedical implants.

From a microstructural perspective, titanium exhibits an allotropic transformation at approximately 882 °C, changing from a hexagonal close-packed α-phase to a body-centered cubic β-phase. This transformation enables a wide range of heat treatment strategies, thereby allowing the tailoring of microstructure and mechanical properties to specific application requirements.

Challenges in Conventional Titanium Manufacturing

Despite the excellent performance of titanium, its manufacturability through conventional routes presents significant limitations, particularly for very small or highly complex geometries. Conventional machining of titanium is associated with high costs and accelerated tool wear, as the material is difficult to cut. Furthermore, subtractive processes such as machining generate considerable material waste, since the volume of removed material often exceeds that incorporated into the final component. When combined with the costs and lead times associated with tooling, fixturing, and post-processing, these factors substantially increase the expense of producing small, complex batches or single-piece custom parts.

Casting and forging methods also face inherent constraints. The fabrication of molds for fine features is challenging, and factors such as cooling rates, grain structure control, porosity, and inclusions can adversely affect the final quality. Additive manufacturing (AM) technologies, such as Laser Powder Bed Fusion (L-PBF), have expanded the possibilities for producing titanium parts and are utilized in most challenging applications in engineering. However, they are still limited by issues of surface finish, minimum feature size, resolution, and the removal of support structures — challenges that are particularly pronounced in miniaturized components.

Sinter-based additive manufacturing approaches promise to overcome some of the limitations of conventional and fusion-based processes, but they also introduce challenges of their own, particularly regarding chemical purity. The use of binder systems to produce the green part necessitates subsequent debinding steps, which can be difficult to control. Since most sinter-based AM technologies are relatively new, the associated material systems have not yet been extensively investigated. Even in well-established sinter-based technologies such as Metal Injection Molding (MIM), maintaining acceptable carbon and oxygen levels remains a critical quality requirement, and this issue continues to limit the broader adoption of these processes for high-performance titanium applications.

Titanium Surgical Tools 3D Printed with LMM

Lithography-based Metal Manufacturing

The Lithography-based Metal Manufacturing (LMM) process addresses many of the challenges associated with conventional and fusion-based manufacturing methods. It enables the production of micro-features, thin walls, lattice structures, and internal channels with resolutions and feature sizes that are difficult or impossible to achieve using traditional approaches. The process also delivers excellent surface quality, thereby reducing — and in some cases eliminating — the need for extensive post-processing.

Compared to other additive or hybrid manufacturing methods, MetShape’s LMM technology provides unrivaled geometric fidelity for micro-scale and highly complex parts. It achieves superior surface quality with minimal post-processing requirements — in many cases eliminating the need for post-processing entirely. The process further reduces lead times for prototypes and small series production, while lowering material waste and therefore the cost per usable part, which is particularly advantageous for high-value materials such as titanium. The process is suitable for both prototyping and series production of small and complex components. Finally, LMM offers exceptional flexibility in meeting tight tolerances, realizing complex internal features, and manufacturing challenging designs that would otherwise require multiple steps or assembly.

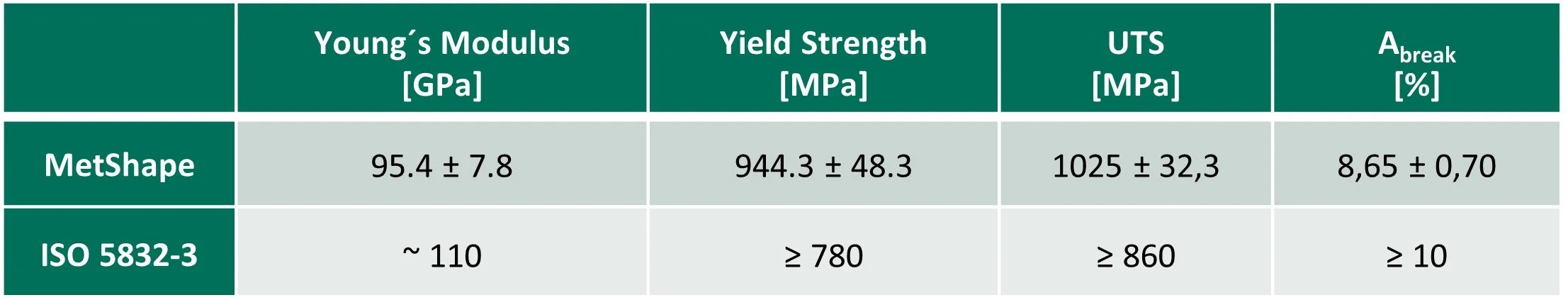

Technical Data: Ti-6Al-4V (Grade 5) & state of the art with the LMM-Technology

In the following section the current state of the art of Ti Grade 5 manufacturing with LMM is given. We are working on process and material development to improve the listed properties. The tables and graphs below summarize the properties for Titanium Grade 5 processed via LMM- Technology, comparing it with the ISO 5832-3 Standard for medical implants and depend on exact processing.

Table 1 Mechanical properties

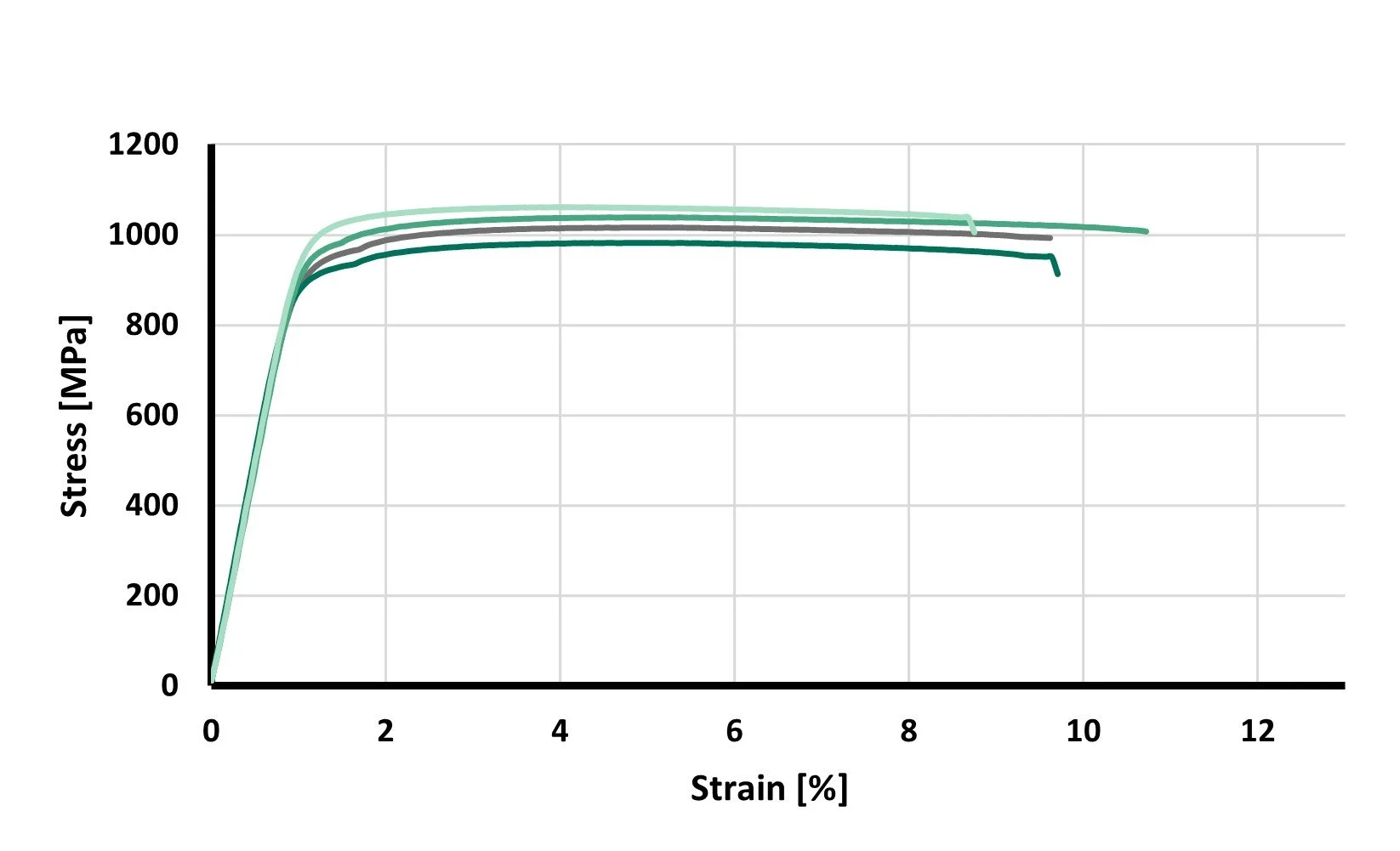

Graph 1 Tensile Test results

As the table with the mechanical properties and the stress strain curves show: The material exceeds both the yield strength and the ultimate tensile strength. However, the values for Young’s modulus and fracture elongation do not meet the targeted standards. While the higher strength can be advantageous for applications involving high loading forces, insufficient Young’s modulus and fracture elongation are critical concerns for medical applications.

These material properties can be explained by considering both the density and the chemical composition. Due to the LMM-technology, complex material systems are required to enable processing with the printer. Although metal powders with the necessary chemical purity are commercially available, they often approach the upper specification limits — particularly with respect to oxygen content. In the binder system, various polymers are required to achieve the target properties during manufacturing. These polymers must be carefully degraded and removed from the high-purity powders along the process chain. Because thermal treatments are necessary for this degradation, and titanium is a highly reactive element, both carbon and oxygen can be readily incorporated into the material. Moreover, depending on the atmospheres used during processing, further pickup of impurities may occur. Ultimately, the parts must be densified by high-temperature sintering which also comes with the risk of impurity pickup.

As shown in the table below, comparing the current results with ISO 5832-3, the present state of the art exceeds the targeted carbon values by 0.044 wt% and the oxygen values by 0.122 wt%. These impurities form precipitates that can account for the higher strength of the material, but at the same time they are responsible for the reduced ductility. In addition, with a density below 96%, the reduced stiffness can also be explained. These parameters need to be optimized to achieve the target quality and properties.

Comparison with ISO 5832-3

Conclusion

At MetShape, we believe that Titanium + LMM is not just a niche option, but a powerful solution for industries that require micro-precision, strength, detail, and efficiency. As the leaders in the application and material development of various alloys for LMM, we are constantly working on optimizing the entire process chain, from the starting material to the final product. Our team is dedicated to solving the manufacturability challenges of titanium for small and complex parts.

If your application requires titanium and you’re hitting limits with machining, casting, or conventional AM, we can help you bring those designs to life, with performance, precision, and speed.

Titanium Dental Implants 3D Printed with LMM