LMM Technology Produces Metallic Surgical Instruments with 3D Printing

Lithography-based Metal Manufacturing (LMM) is transforming the way high-precision metal components are produced — especially for medical and surgical applications. The technology enables the additive manufacturing of complex, miniaturized, and high-quality metal instruments, making it ideal for use in minimally invasive procedures where precision and surface finish are critical.

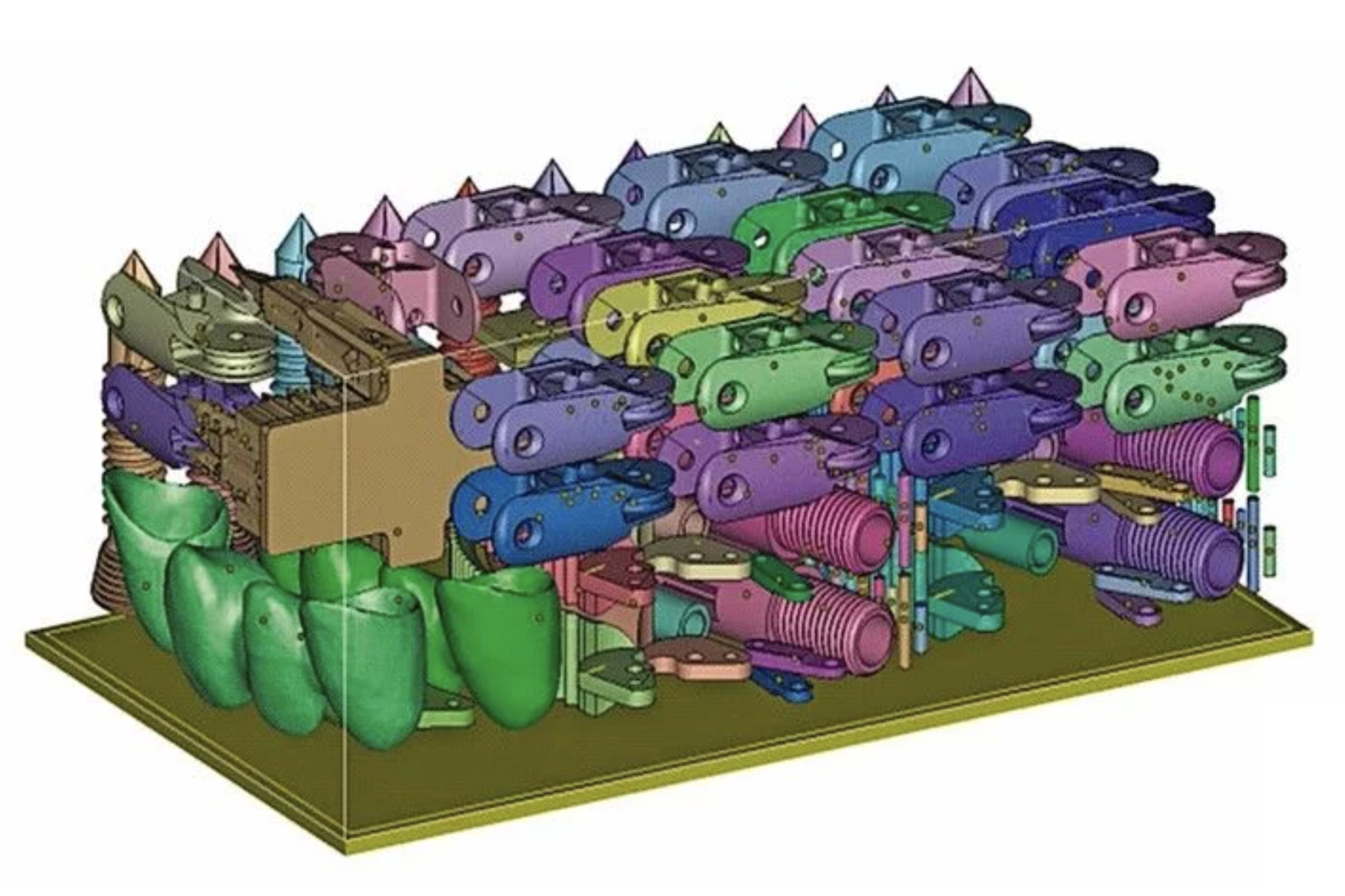

Optimized part placement maximizes 3D printer build volume for peak production efficiency.

The Challenge: Precision Tools for Minimally Invasive Surgery

Modern surgical tools often feature intricate geometries and are made from hard-to-machine materials such as titanium or stainless steel. Traditional manufacturing methods, including CNC machining, quickly reach their limits when producing such delicate components in small quantities.

While 3D printing (additive manufacturing) has opened new possibilities for complex designs, conventional metal 3D printing processes — particularly laser-based methods — still face significant challenges:

Limited surface quality

The need for support structures

Costly post-processing

Thermal distortion and internal stresses

These issues often make it difficult to justify additive manufacturing economically, particularly for small-scale or precision-critical medical components.

The Solution: Lithography-based Metal Manufacturing (LMM)

Metshape GmbH, based in Pforzheim, Germany, specializes in LMM technology, offering a breakthrough approach for additive manufacturing of metallic precision components.

Unlike traditional powder bed fusion methods, LMM enables the production of dense, high-resolution metal parts with excellent surface finishes — without the need for support structures.

According to Dr. Andreas Baum, Professor of Manufacturing Engineering with a focus on Metal Additive Manufacturing

“In most cases, the cost-intensive post-processing steps exclude additive manufacturing from being economically viable. Our LMM technology eliminates that barrier by producing precision parts with outstanding surface quality — directly from the process.”

How LMM Works

The LMM process is inspired by stereolithography, combining high-resolution photopolymerization with metal powder sintering.

Step 1: Forming the Green Part

A feedstock made of metal powder and a photosensitive polymer binder is exposed to light through a digital mask. The polymer hardens where exposed, binding the metal powder layer by layer to form a high-precision “green part.”

Step 2: Sintering

The green part is then thermally processed in two stages:

The polymer binder is removed.

The remaining metal powder is sintered into a fully dense, high-strength metallic part.

This process results in porosity-free, support-free components comparable in material properties to parts made using Metal Injection Molding (MIM) — but with the design freedom and precision of additive manufacturing.

Key Advantages of LMM Technology

No support structures required, enabling parts with all-around functional surfaces

Superior surface finish compared to laser-based methods

Higher design freedom for complex and miniaturized geometries

Efficient build space utilization — parts can be densely packed during printing

Cost-effective production of small series and custom designs

A micro metal part 3D printed using Lithography-based Metal Manufacturing (LMM) in 17-4 PH stainless steel.

Material Capabilities

Currently, Metshape’s LMM process supports stainless steel 316L and titanium, with ongoing development of hardenable and difficult-to-machine alloys. The company continuously expands its material portfolio to meet the demanding requirements of the medical device industry.

From Feasibility Study to Turnkey Production

Metshape’s business model is built on three complementary pillars that guide customers from concept to production:

Feasibility Studies – Evaluating the suitability of LMM for specific parts and applications.

Contract Manufacturing – Offering serial production services for clients without in-house additive capabilities.

Turnkey Solutions – Supporting full integration of LMM technology into the customer’s own production environment, including equipment setup, training, and maintenance.

This end-to-end approach ensures customers benefit from expert guidance throughout the entire process chain — maximizing both performance and return on investment.

Enabling the Future of Precision Metal 3D Printing

As the medical technology sector continues to demand greater precision, miniaturization, and design flexibility, LMM stands out as a scalable and reliable solution for producing metallic surgical instruments and components.

By eliminating post-processing challenges and enabling unprecedented precision, Metshape’s LMM technology is helping to shape the future of additive manufacturing in MedTech.

Read the full article here:

https://medizin-und-technik.industrie.de/3d-druck/lmm-technologie-fertigt-metallische-praezisionsbauteile-im-3d-druck/#slider-intro-2