Our Materials

Our expertise in LMM and materials science is precisely aligned to produce micro metal parts with the properties your application demands. Explore our available materials below, and if your project requires a specific alloy, we offer tailored material development to match your needs.

Stainless Steel 316L

316L is an austenitic stainless steel with very low carbon content (under 0.03%). Components from this alloy exhibit outstanding corrosion resistance, excellent ductility, and non-magnetic behavior. These characteristics make it well suited for applications requiring maximum chemical inertness.

Stainless Steel 17-4PH

17-4PH is a precipitation-hardening martensitic stainless steel known for offering both strong corrosion resistance and excellent mechanical strength. Components produced from this alloy are also magnetic, making it a suitable choice for applications where magnetic behavior is required.

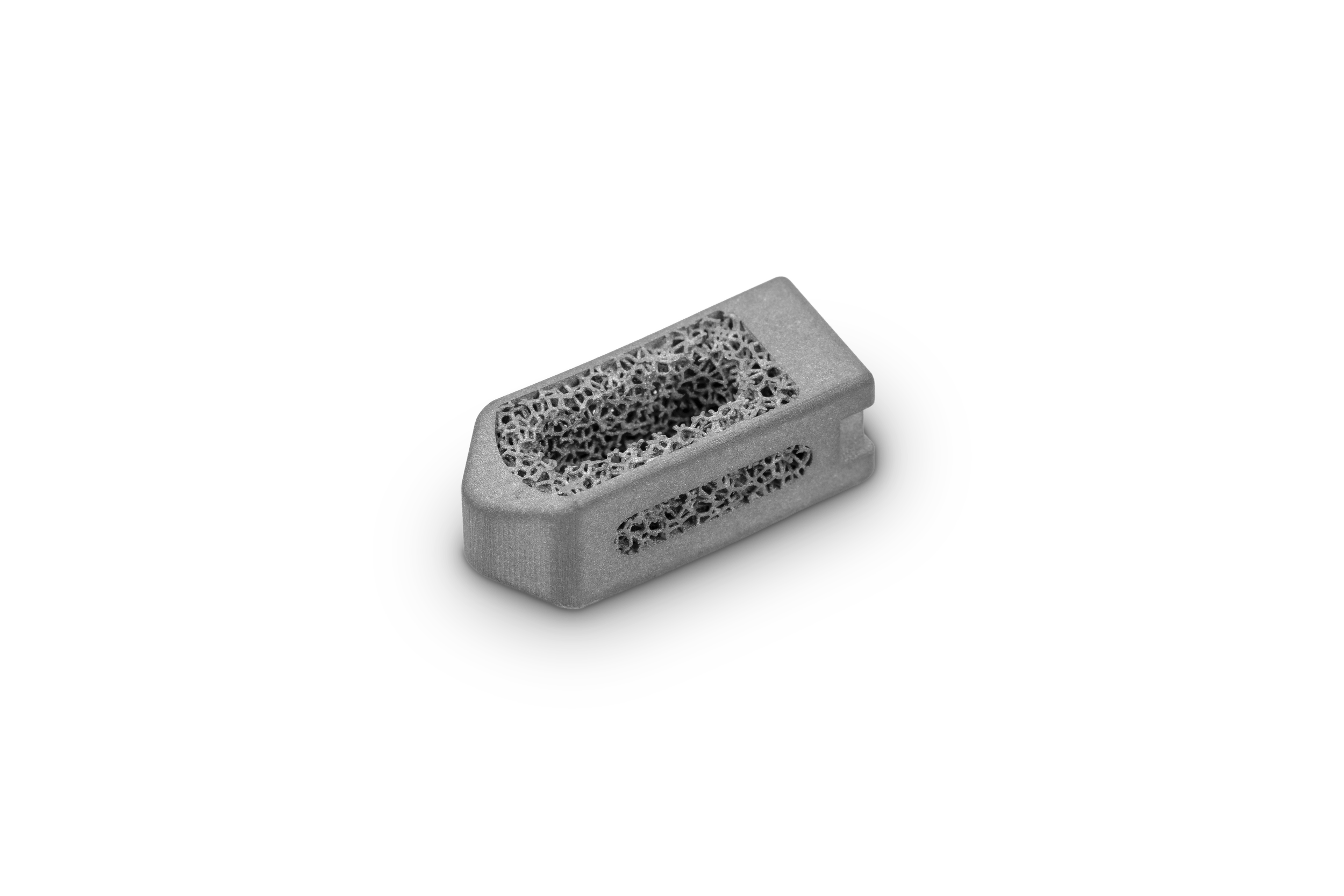

Titanium Grade 5

Ti-6Al-4V is a titanium alloy valued for its outstanding corrosion resistance and high strength-to-weight ratio. Its favorable mechanical and chemical properties make it ideal for producing lightweight components, particularly in biomedical applications where biocompatibility is essential.

Nitinol

Nitinol is a nickel-titanium alloy distinguished by its unique shape-memory and superelastic characteristics. Components made from this material can withstand significant deformation and recover their original form, while also offering good corrosion resistance and biocompatibility. These properties make it ideal for applications requiring controlled flexibility and precise mechanical performance.

Need a custom material for your application?

We’ll develop it for you.

Our team combines product development expertise, in-depth knowledge of LMM technology, and advanced materials science to create solutions tailored to your application, ensuring the right properties for performance, reliability, and scalability.