-

Introduction to Lithography-based metal manufacturing (LMM)

Learn how Lithography-based Metal Manufacturing (LMM) combines high-resolution 3D printing with scalable powder metallurgy to enable complex, high-accuracy metal parts.

-

Titanium Grade 5 & Lithography-based Metal Manufacturing (LMM)

Learn how Titanium Grade 5 and Lithography-based Metal Manufacturing (LMM) enable 3D printing of strong, lightweight titanium parts for advanced applications.

-

3d printed micro metal parts bring innovation to space

Learn how Lithography-based Metal Manufacturing (LMM) enables high-precision 3D printing of micro metal parts for innovative experiments on the International Space Station.

Explore all articles, guide and more

Unlocking the 3D Printing Potential of LMM for Medical Devices

Metshape GmbH is redefining what’s possible in medical technology with Lithography-based Metal Manufacturing (LMM) — an additive process that creates ultra-fine, complex metal parts at scale. From Nitinol components for catheters to next-generation surgical tools, discover how this German company’s microfabrication expertise is attracting more global attention than ever before.

LMM Technology Produces Metallic Surgical Instruments with 3D Printing

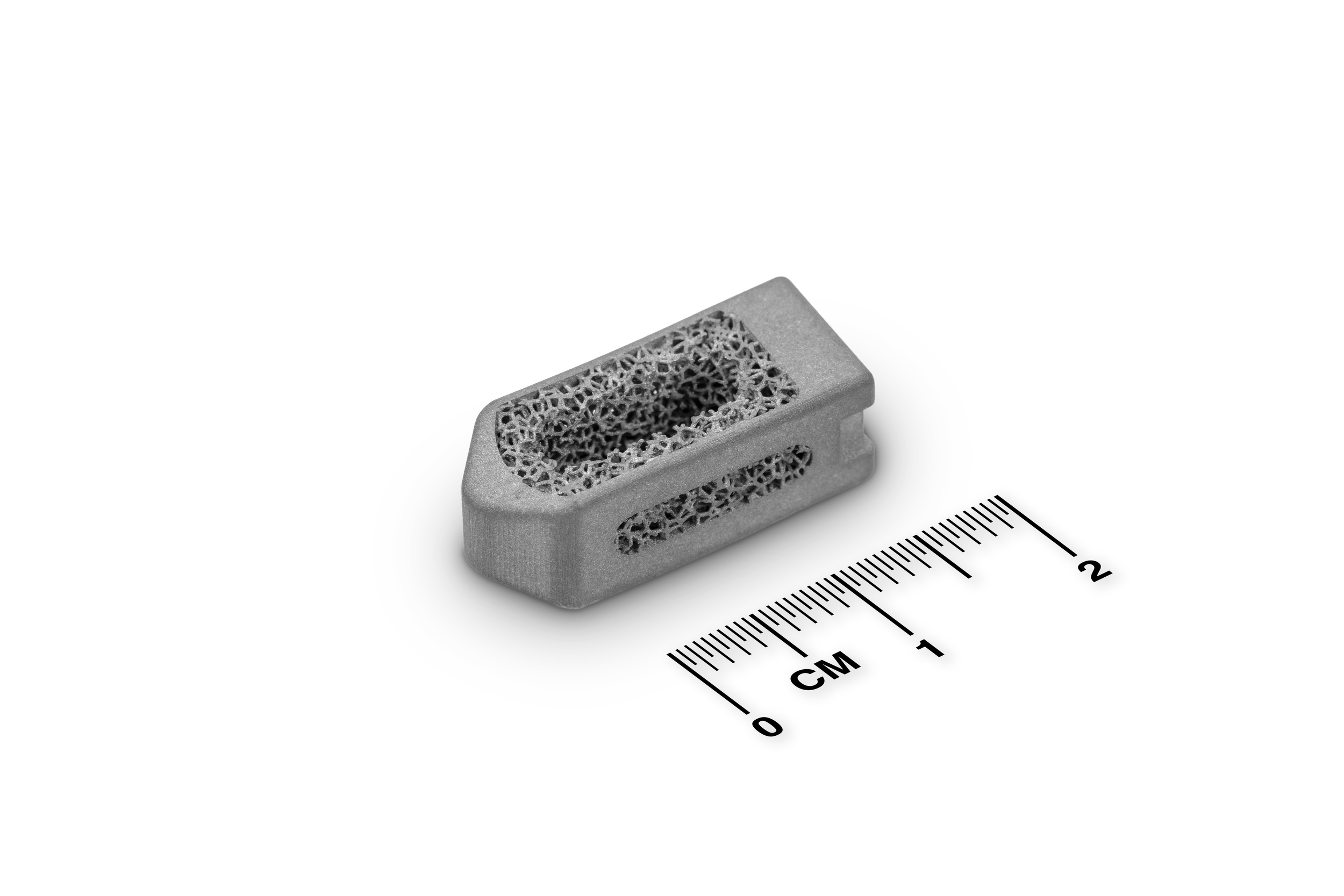

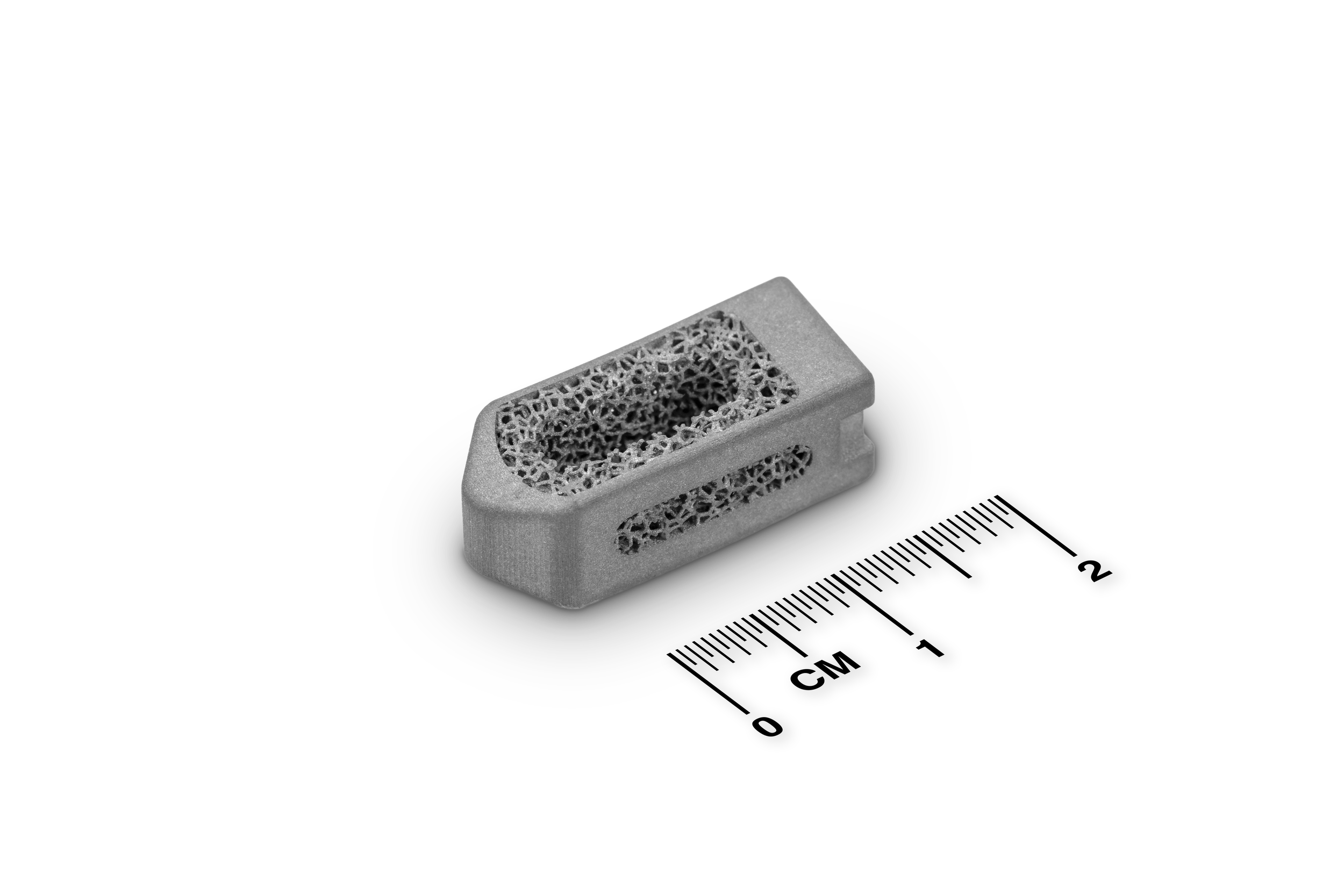

Lithography-based Metal Manufacturing (LMM) is transforming the way high-precision metal components are produced — especially for medical and surgical applications. The technology enables the additive manufacturing of complex, miniaturized, and high-quality metal instruments, making it ideal for use in minimally invasive procedures where precision and surface finish are critical.

Titanium Grade 5 & Lithography-based Metal Manufacturing (LMM) — Key Insights

Discover how Titanium Grade 5 combined with Lithography-based Metal Manufacturing (LMM) is pushing the limits of engineering. From tiny, intricate parts to cutting-edge applications, learn why this pairing is transforming what’s possible — and see the latest developments at MetShape.

Introduction to Lithography-based metal manufacturing

Learn how Lithography-based Metal Manufacturing (LMM) combines high-resolution 3D printing with scalable powder metallurgy to enable complex, high-accuracy metal parts.

Compensating for Sintering Distortion in LMM

Discover how MetShape and ISEMP developed a simulation-based solution to predict and compensate sintering distortion in LMM, making high-volume, high-precision metal 3D printing production-ready.

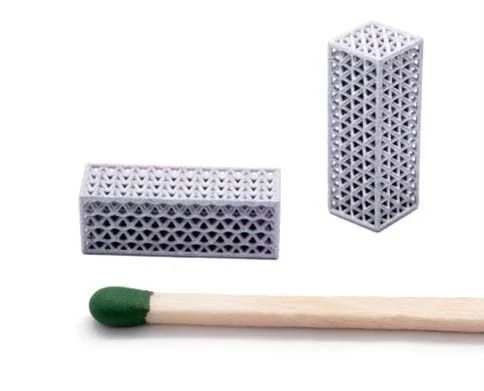

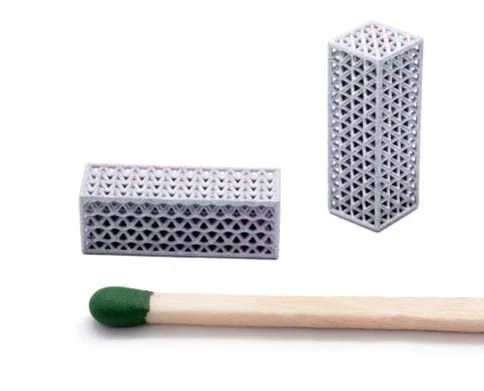

3d printed micro metal parts bring innovation to space

High school students are pushing the boundaries of space research with cutting-edge 3D printing. Using Lithography-based Metal Manufacturing (LMM), they turned highly complex micro lattice designs into reality for an experiment on the International Space Station — a perfect example of how additive manufacturing is unlocking new possibilities for precision metal parts.