Lithography-based Metal Manufacturing

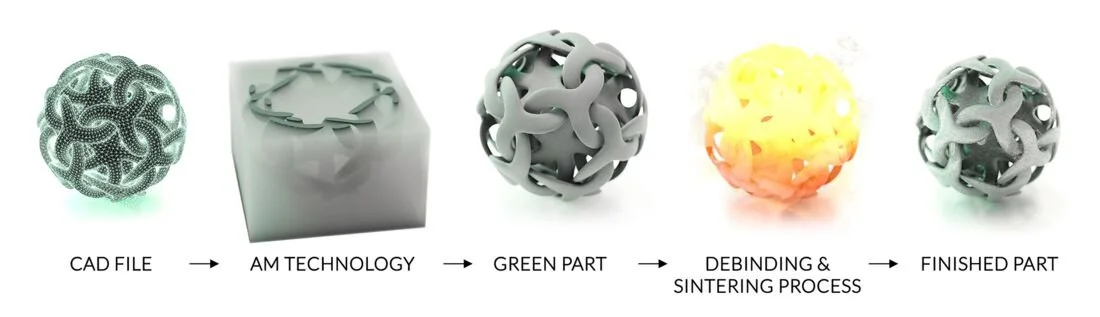

Lithography-based Metal Manufacturing (LMM) is a sinter-based additive manufacturing (AM) process that involves two steps.

The feedstock consists of a mixture of metal powder and a photosensitive polymer binder. This material is applied to a build platform and selectively cross-linked from above using UV light through mask exposure. Layer by layer, a "green part" is formed.

This green part then undergoes debinding and sintering to produce the final metal component.

The benefits of sinter-based additive manufacturing result from its unique process, which begins by printing a green part that is subsequently debound and sintered. This technology offers high productivity and eliminates the need for support structures, significantly improving surface quality and reducing costly post-processing. The final component properties are comparable to those achieved with established Metal Injection Molding (MIM) technology. In addition, it allows you to fully leverage the design freedom that 3D printing offers, enabling the production of complex and customized geometries.

Key Characteristics

Ideally for small, complex parts < 30mm

Offers high accuracy

Single-step printing - no tooling required

Technical properties

Surface: Ra ~ 2-3 µm

Tolerances: ±0.05 mm

Layer thickness: 10-60 µm

Materials

316L Stainless steel

17-4PH Stainless steel

Titanium Grade 5